6 اسفند 1398

معرفی اصغر روفه گر حق

استاد مرحوم اصغر روفه گر حق به دلیل سال ها تلاش و نوآوری در حوزه…

29 خرداد 1401

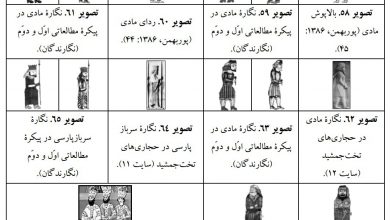

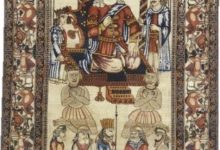

طراحی و طراحان فرش در دربار اسکندر سلطان قسمت اول

نسخه های فراوانی در دوران اندک حکومت اسکندر سلطان در شیراز مصور شده که از…

15 دی 1396

کشور آمریکا

در دهه های اخیرآمریکا از نظر وزنی و ارزشی دومین کشور واردکننده فرش دستباف بوده…